The #1 Mistake Americans Make with DIY Plumbing (And How to Avoid It)

DIY plumbing projects can save you money and give you a real sense of accomplishment. But there’s one mistake that trips up almost every homeowner who picks up a wrench – and it’s costing people thousands in repairs every year.

The #1 mistake Americans make with DIY plumbing is over-tightening connections. It sounds simple, but this innocent error causes more leaks, cracks, and expensive repairs than any other DIY mishap.

Why Over-Tightening Is Such a Big Deal

When you’re working on plumbing, your first instinct is probably “tighter equals better,” right? Makes sense – you want everything secure and leak-proof. But plumbing doesn’t work that way.

Over-tightening puts way too much stress on fittings, pipes, and threads. Think of it like trying to open a pickle jar that someone screwed on way too tight. Eventually, something’s going to give – either the jar lid cracks, or you hurt your hand trying to open it.

The same thing happens with plumbing connections. When you crank down too hard on:

- Pipe fittings

- Elbows and tees

- Galvanized connections

- Coupling joints

You’re creating stress points that will fail later. Sometimes right away, but often weeks or months down the road when water pressure finds that weak spot you created.

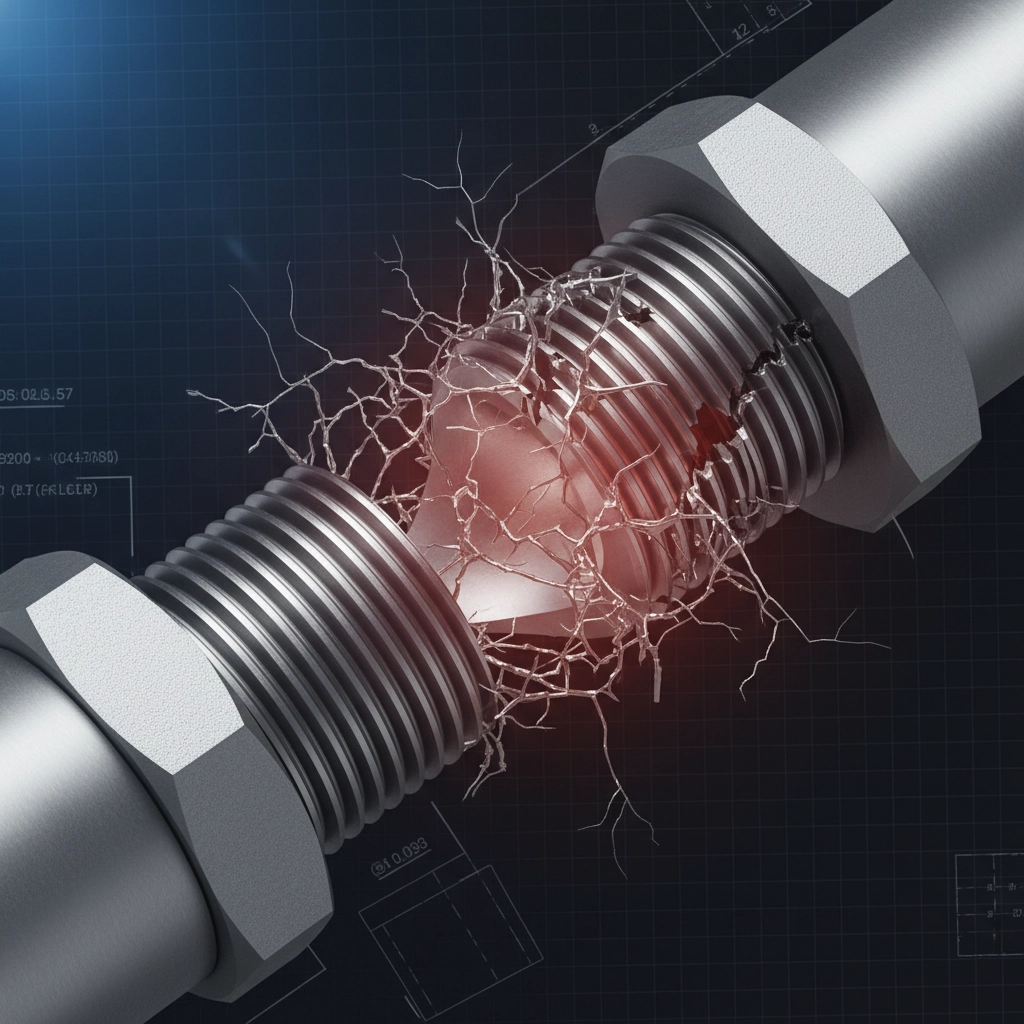

The Hidden Damage You Can’t See

Here’s what makes over-tightening so sneaky – the damage isn’t always obvious right away. You might finish your project feeling proud that everything’s tight and secure. But underneath, you’ve created tiny cracks or damaged threads that will turn into big problems.

These stress fractures start small. Water finds its way into these weak spots, and over time, they expand. What started as a hairline crack becomes a full leak. What seemed like a solid connection starts dripping, then streaming, then flooding your basement.

We’ve seen homeowners who thought they did everything right, only to call us six months later with water damage that could have been prevented with the right technique from the start.

What Actually Happens When You Over-Tighten

Let’s get specific about what goes wrong:

Cracked Fittings: Brass, copper, and PVC fittings all have their limits. Push past those limits, and they crack. Sometimes you’ll see the crack right away, but often it’s internal and only shows up when water pressure hits it.

Stripped Threads: Over-tightening can strip the threads on both male and female connections. Once threads are stripped, that connection will never be reliable again. You’ll need to cut out that section and start over.

Bent Pipes: Thin-walled pipes like copper can actually bend or kink when you apply too much torque. This creates restrictions in water flow and weak points that fail under pressure.

Damaged Seals: O-rings and rubber gaskets can get pinched or damaged when connections are over-tightened. These seals are what actually prevent leaks – damage them, and your connection will leak no matter how tight it is.

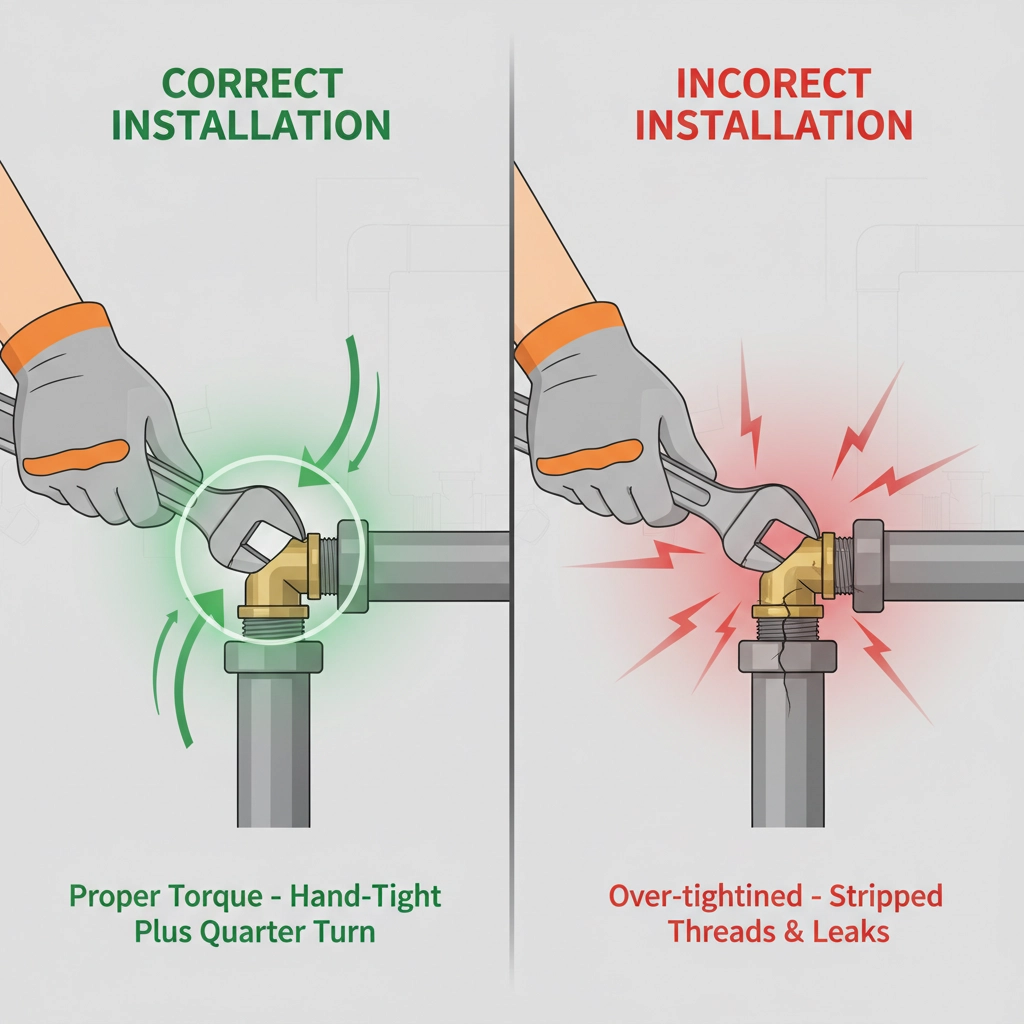

The Right Way to Tighten Plumbing Connections

So what’s the secret? Professional plumbers follow a simple rule: “Hand-tight plus a quarter turn.”

Here’s how it works:

- Start by hand: Thread the connection together by hand until it’s snug. This ensures the threads are properly aligned and engaged.

- Add a quarter turn: Use your wrench to turn the connection just 1/4 turn more. That’s it. Not a half turn, not “until it feels really tight” – just a quarter turn.

- Test and adjust: Turn on the water and check for leaks. If there’s a small drip, you can add another small turn. But resist the urge to keep cranking.

This technique works because it creates a secure seal without putting dangerous stress on the materials. The connection is tight enough to prevent leaks but not so tight that it damages the fitting.

Tools Make a Huge Difference

Using the right tools is just as important as using the right technique. Here’s what you should have:

Pipe Wrenches: These give you better control and leverage than regular wrenches. They’re designed specifically for plumbing work.

Channel Lock Pliers: Great for holding pipes steady while you work on connections.

Pipe Cutters: Clean, straight cuts make better connections. Hacksaw cuts can leave burrs that interfere with proper threading.

Thread Sealant or Tape: This helps create a watertight seal without over-tightening.

Never use regular pliers or adjustable wrenches on plumbing connections. They don’t grip properly and make it easy to apply uneven pressure that damages fittings.

Common Scenarios Where Over-Tightening Happens

Replacing a Faucet: You’re excited to install that new kitchen faucet, so you really crank down on those supply line connections. But those compression fittings only need to be snug – over-tightening can crack the valve seat inside your shut-off valve.

Fixing a Leaky Joint: You see a drip and think, “I’ll just tighten this up a bit more.” But that drip might be caused by a damaged seal, not a loose connection. Tightening more just makes the damage worse.

Installing New Fixtures: Whether it’s a toilet, sink, or showerhead, new installations make people nervous. That nervousness often translates into over-tightening everything “just to be sure.”

Red Flags That You’ve Over-Tightened

Watch out for these warning signs:

- Resistance increases suddenly: If a fitting was turning easily and then suddenly gets very hard to turn, stop immediately.

- Creaking or cracking sounds: These sounds mean something is under too much stress.

- The fitting feels “spongy”: This can indicate internal cracking in the material.

- Threads feel rough: Smooth threading should feel consistent. If it starts feeling rough or gritty, you might be stripping threads.

When DIY Becomes “Call the Pros”

Look, we love that homeowners want to tackle their own projects. But some situations are definitely worth calling American Trail Plumbing:

- Gas lines: Never DIY gas connections. The stakes are just too high.

- Main water lines: These require special tools and knowledge.

- Sewer connections: Health codes and proper technique are crucial.

- When you’re not sure: If you’re questioning whether you’re doing it right, trust that instinct.

Prevention Is Your Best Friend

The best way to avoid over-tightening problems is to take your time and use the right approach from the start. Here are our top tips:

Practice on scraps first: If you’re new to plumbing, practice the “hand-tight plus a quarter turn” rule on some practice fittings before working on your real project.

Mark your starting point: Use a marker to mark the position of your fitting before you start tightening. This helps you see exactly how far you’ve turned it.

Test frequently: Don’t wait until the entire project is done to test for leaks. Test each connection as you go.

Keep thread sealant handy: Teflon tape or pipe thread compound can help create a seal without over-tightening.

The Bottom Line

Over-tightening might seem like playing it safe, but it’s actually creating bigger problems down the road. The good news? Once you understand the right technique, it’s actually easier than what most people are doing wrong.

Remember: plumbing connections should be snug and secure, not stressed and strained. When in doubt, err on the side of slightly loose – you can always tighten a bit more, but you can’t un-crack a fitting.

If you’re planning a DIY plumbing project and want to make sure you’re doing it right, give American Trail Plumbing a call. We’d rather help you avoid problems than fix expensive damage later. Sometimes a quick consultation can save you hundreds in repairs and give you the confidence to tackle your project the right way.

Your home’s plumbing system will thank you for taking the time to do it right the first time.